RockRebar®

A Green, Sustainable Alternative to Rusty, Steel Rebar.

Basalt World Corp's innovative solution to our nations crumbling infrastructure.

RockRebar® (BFRP / Basalt rebar)

RockRebar® ( BFRP / Basalt rebar) is a product that when tested, proved to be only 1/4th the weight of steel, yet proved to have a higher tensile strength than traditional steel rebar. The June 2016 official printing of AC-454 now labels continuous basalt fiber and a special manmade fiberglass E-CR (corrosion resistant) fiberglass as sufficiently similar in overall performance as to be interchangeable for use in producing FRP concrete reinforcements. Brown basalt fiber reinforced polymer BFRP rebar and the white fiberglass GFRP rebar are now the only two “glass state” structural fibers officially recognized for concrete reinforcement. Naturally, occurring basalt has several advantages.

RockRebar® ( BFRP / basalt rebar) is based on one component, NATURALLY renewable Basalt rock (lava). Basalt covers 70% of the earth's surface. Unlike fiberglass you don't need toxic chemicals to create Basalt and no contaminated waste is created from its production. Basalt is abundant, cost effective, self-sustainable and eco-friendly. Basalt rock is crushed and loaded into a furnace where it’s melted at extreme temperatures. The molten rock is further processed by being drawn through platinum bushings. As the fibers are drawn from the bushings, they are stretched taut, decreasing their diameter up to 90 percent. Finally, the basalt exits the assembly as a continuous, "glass-state" fiber, which is referred to as continuous basalt fiber (or CBF).

We take thousands of continuous strands of Basalt fiber which are compressed until they form a cylinder-type shape. During this process, they are coated with our proprietary epoxy resin, which acts like an adhesive to give the RockRebar® an enhanced bonding surface. Before the final setting, a Dacron strand is wrapped tightly around the fibers, creating a shape change to ensure it will grip with the concrete. A coating of sand is then applied to the bundle. The final result is RockRebar®, an industry recognized, innovative replacement for traditional black steel rebar..

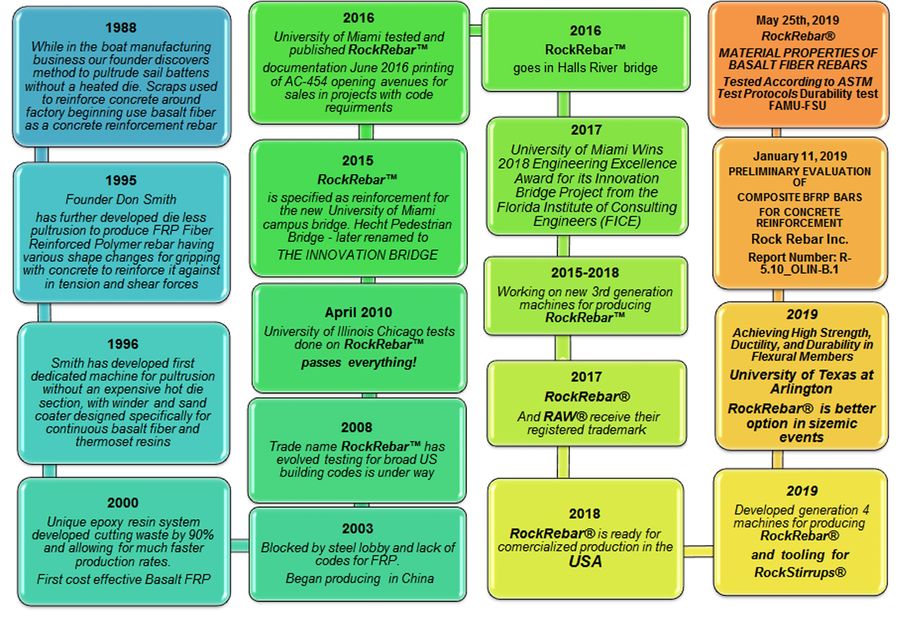

HISTORY OF ROCKREBAR®

Photo Gallery / POOLS / BRIDGES / FOUNTAINS / sea walls

Get a Quote for RockRebar® Reinforcements

basaltworldcorp.com

Disclaimer

This information and data contained herein is offered solely as a guide in the selection of product. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume any responsibility or liability arising out of its use or performance. The user agrees to be responsible for thoroughly testing any application of the product to determine its suitability. Because of numerous factors affecting results, we make no warranty of any kind, express or implied, including those of merchantability and fitness for a particular purpose.

Statements in this publication shall not be construed as representations or warranties or as inducements to infringe any patent or violate any law, safety code or insurance regulation. We reserve the right to modify this document without prior notice.